Technical Note 3: GCCM Flexural Strength ASTM D8058

Introduction

This series of Technical Notes consider the importance of using GCCM (Geosynthetic Cementitious Composite Mat) specific ASTM standards when selecting GCCM materials for use on erosion control projects:

The Problem:

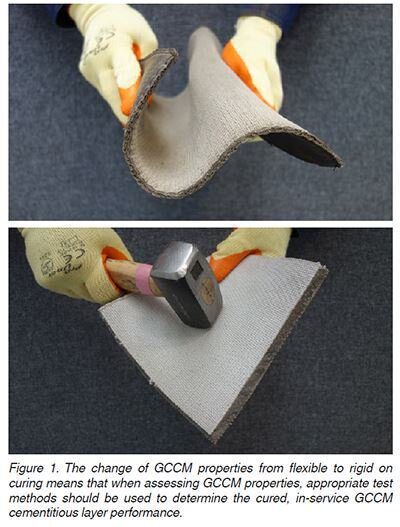

GCCMs are unlike most geosynthetics as their properties change on hydration from flexible to rigid. Both the uncured (pre-set, soft and flexible) and cured (post-set, hardened and rigid) properties need to be reported to understand the GCCM capabilities in both deployment and in-service respectively.

GCCMs contain geosynthetic and cementitious materials, both of which possess very different physical properties. Geosynthetics are typically buried and their performance is often assessed according to their tensile strength, whereas hardened cementitious materials are often exposed and their performance is typically assessed according to their compressive strength, which is typically correlated with other key characteristics such as abrasion resistance, freeze thaw resistance and resistance to chemical attack.

GCCMs are the only geosynthetic to contain unset cementitious material and pre-existing geosynthetic test standards do not include methods for understanding the performance of the cementitious material contained within a GCCM. It is therefore important to test the properties of the cured cementitious material so that the behaviour of the GCCM as a hardened composite can be understood. It is also critical to ensure the cementitious material is cured at a water/powder ratio that is representative of field (in-service) hydration and not artificially controlled in the laboratory.

The Solution:

Since 2015, the ASTM International Standards Organisation and its D35 Geosynthetics Committee has published a number of standards specifically for GCCMs to address the shortfalls in using pre-existing geosynthetic or concrete standards. These GCCM specific standards enable consistent, accurate reporting of essential GCCM properties.

They include:

• ASTM D8364 ‘Standard Specification for GCCM materials’

• ASTM D8329 ‘Standard Test Method for Determination of Water/Cementitious Materials Ratio for GCCMs and

Measurement of the Compressive Strength of the Cementitious Material Contained Within’

• ASTM D8058 ‘Standard Test Method for Determining the Flexural Strength of a GCCM Using the Three-Point

Bending Test’

• ASTM D8030 ‘Standard Practice for Sample Preparation for GCCM’

These standards have been created to ensure that repeatable testing and reporting of GCCM properties is conducted on specimens that have been prepared in a manner that is consistent with their use in the field, so the test results are representative of GCCMs installed in real-world operating conditions. Applying non-GCCM tests can result in properties that vary by an order of magnitude from field properties.

This Technical Note 3 focusses on the importance of using ASTM D8058 for determining the flexural strength of GCCMs.

ASTM D8058 GCCM Flexural Strength:

GCCMs behave as composite materials, they combine the benefits of geosynthetics and concrete. Broadly speaking, conventional geosynthetics are strong in tension and weak in compression, whereas concrete is strong in compression but weak in tension.

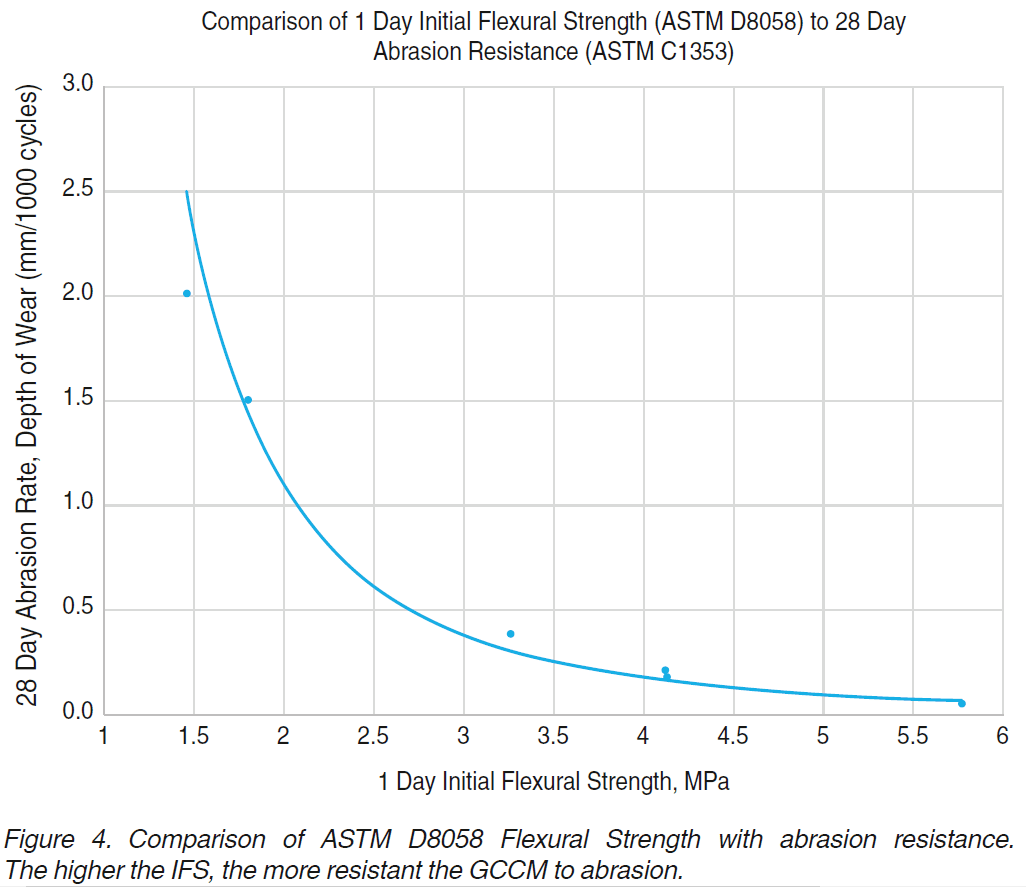

Flexural Strength testing of cured GCCMs provides the best overall indication of the in-service performance of a GCCM by compressing one surface while simultaneously extending the other and is considered the standard index test for this class of material.

The internationally recognised standard for flexural strength testing of GCCMs is ASTM D8058 ‘Standard Test Method for Determining the Flexural Strength of a GCCM Using the Three-Point Bending Test’.

What is ASTM D8058:

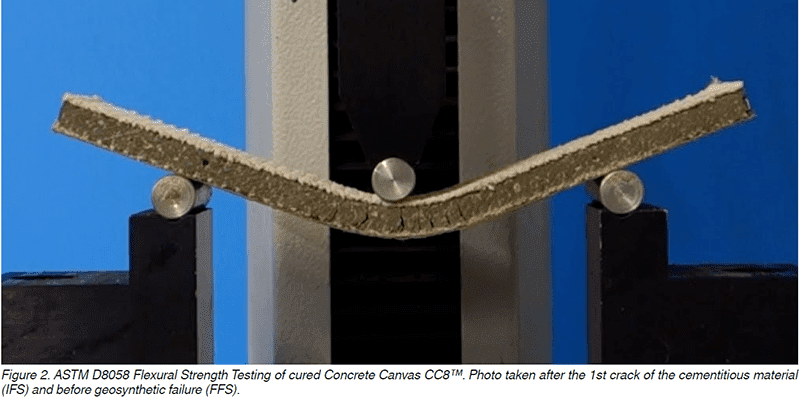

ASTM D8058 uses a constant rate of extension testing machine with a 3-point fixture set up to continuously measure the stress and displacement of a cured GCCM specimen as it is loaded to failure. By studying the results, ASTM D8058 enables the composite performance of a GCCM to be understood by determining both the Initial Flexural Strength (IFS), which is governed by the cementitious material, and the Final Flexural Strength (FFS), when the geosynthetic components fail.

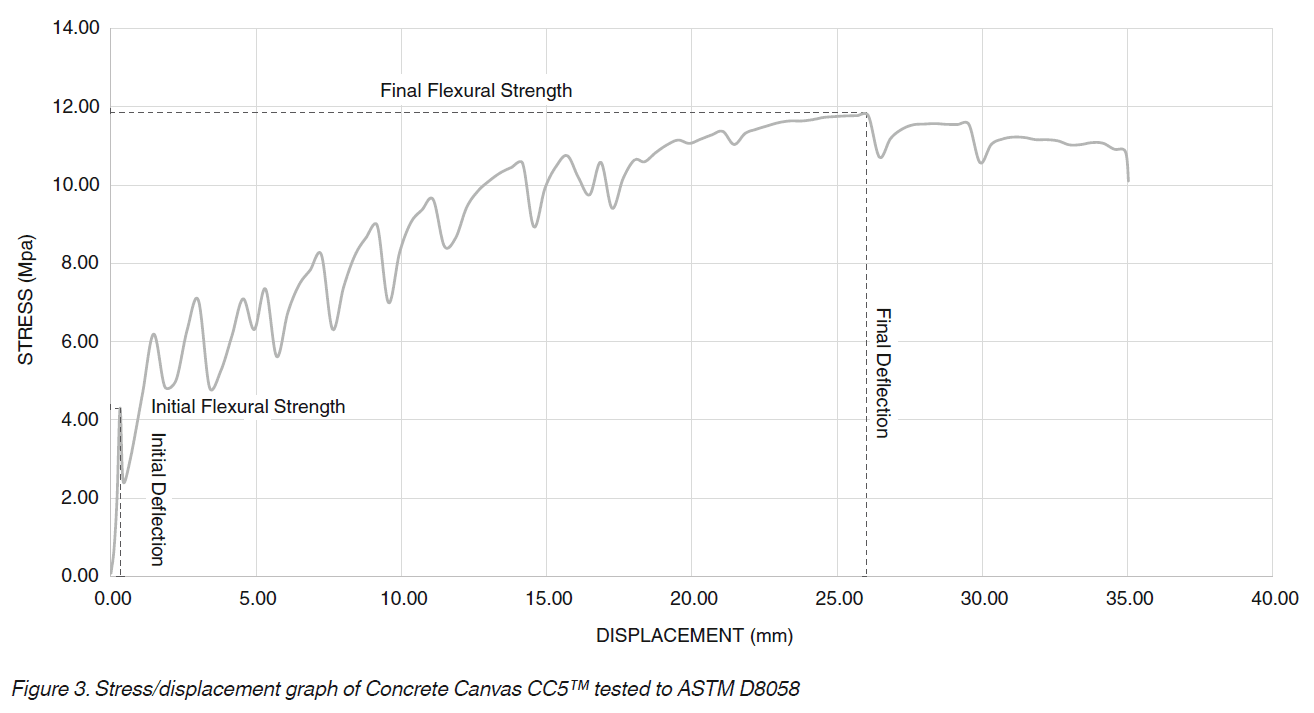

An example stress/displacement graph generated by flexural testing of a GCCM to ASTM D8058 is presented in Figure 3 and demonstrates a semi ductile failure in 3 phases:

1. First, the initial elastic phase where the displacement is reversible. This phase always precedes the first crack of the cementitious material, which is the IFS. The specimen In Figure 3 has an IFS exceeding 4MPa;

2. Second, the GCCM ruptures in a saw tooth pattern of progressive concrete failure and fibre loading;

3. Finally, ultimate failure occurs as the geosynthetic fibres themselves reach their ultimate loading limit, which is the FFS.

After the IFS is reached and the cementitious material in the GCCM first cracks, its composite behaviour is changed as the fibres take up the load that was previously carried by the rigid concrete layer. The IFS of a GCCM may have a significantly lower strength than its FFS, which may not be recorded until very large deflections are reached. Such large deflections are unlikely to be seen in any typical application. Therefore when assessing the Flexural Strength of GCCMs, the primary index for comparison should be the Initial Flexural Strength. Specimens must be prepared in accordance with GCCM sample preparation standard ASTM D8030 and tested in accordance with ASTM D8058.