Technical Note 2: GCCM Compressive Strength ASTM D8239

Introduction

This series of Technical Notes consider the importance of using GCCM* specific ASTM standards when selecting GCCM materials for use on erosion control projects:

The Problem:

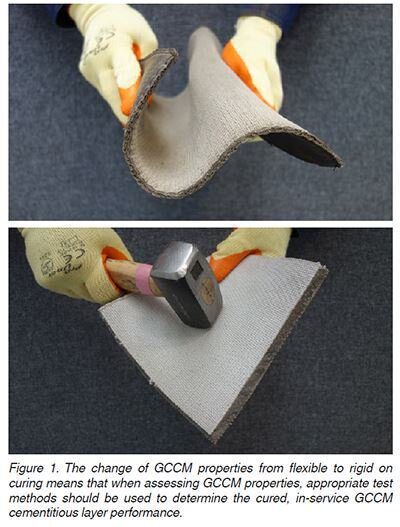

GCCMs are unlike most geosynthetics as their properties change on hydration from flexible to rigid. Both the uncured (pre-set, soft and flexible) and cured (post-set, hardened and rigid) properties need to be reported to understand the GCCM capabilities in both deployment and in-service respectively.

GCCMs contain geosynthetic and cementitious materials, both of which possess very different physical properties. Geosynthetics are typically buried and their performance is often assessed according to their tensile strength, whereas hardened cementitious materials are often exposed and their performance is typically assessed according to their compressive strength, which is typically correlated with other key characteristics such as abrasion resistance,

freeze thaw resistance and resistance to chemical attack.

GCCMs are the only geosynthetic to contain unset cementitious material and pre-existing geosynthetic test standards do not include methods for understanding the performance of the cementitious material contained within a GCCM. It is therefore important to test the properties of the cured cementitious material so that the behaviour of the GCCM as a hardened composite can be understood. It is also critical to ensure the cementitious material is cured at a water/powder ratio that is representative of field (in-service) hydration and not artificially controlled in the laboratory.

The Solution:

Since 2015, the ASTM International Standards Organisation and its D35 Geosynthetics Committee has published a number of standards specifically for GCCMs to address the shortfalls in using pre-existing geosynthetic or concrete standards. These GCCM specific standards enable consistent, accurate reporting of essential GCCM properties.

They include:

• ASTM D8364 ‘Standard Specification for GCCM materials’

• ASTM D8329 ‘Standard Test Method for Determination of Water/Cementitious Materials Ratio for GCCMs and Measurement of the Compressive Strength of the Cementitious Material Contained Within’

• ASTM D8058 ‘Standard Test Method for Determining the Flexural Strength of a GCCM Using the Three-Point Bending Test’

• ASTM D8030 ‘Standard Practice for Sample Preparation for GCCM’

These standards have been created to ensure that repeatable testing and reporting of GCCM properties is conducted on specimens that have been prepared in a manner that is consistent with their use in the field, so the test results are representative of GCCMs installed in real-world operating conditions. Applying non-GCCM tests can result in properties that vary by an order of magnitude from field properties.

This Technical Note 2 focusses on the importance of using ASTM D8329 for determining the compressive strength of the cementitious layer of GCCMs.

ASTM D8329 GCCM Compressive Strength:

The only accurate method of determining the compressive strength of the cured cementitious material within a GCCM is by testing to ASTM D8329 ‘Standard Test Method for Determination of Water/Cementitious Materials Ratio for GCCMs and Measurement of the Compressive Strength of the Cementitious Material Contained Within’.

What is ASTM D8329:

Conventional concrete compressive strength testing (for example ASTM C109) is conducted by casting a cube (typically 50 or 100mm) and loading it to failure. Since GCCMs cannot be cast into cubes, the cementitious material must be removed from the GCCM and cast into a cube at the appropriate water/cement ratio prior to load testing.

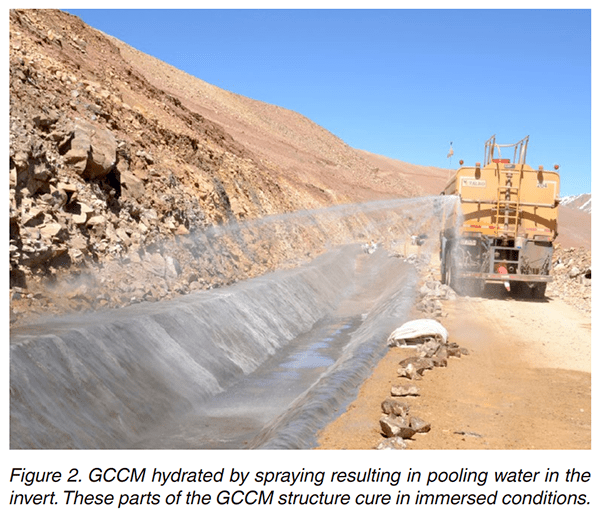

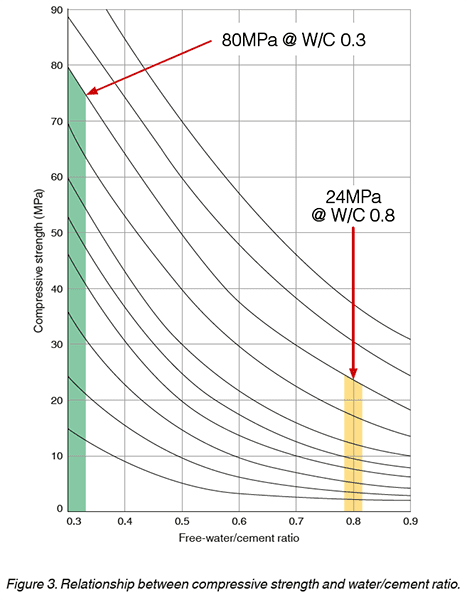

GCCMs are hydrated in the field by spraying or immersion and whilst the hydration water is often applied by spraying, immersion almost always occurs in the field due to pooling of water on the surface of the GCCM. When testing for GCCM compressive strength it is essential that the water/ cement ratio used in the cube testing is representative of the ratio achieved during hydration of the GCCM on site, in the worst-case situation.

ASTM D8329 therefore sets out the procedure for determining the appropriate water/cementitious materials ratio in a GCCM that is representative of site hydration conditions based on full immersion.

Cured GCCMs typically consist of three components; the polymeric/geosynthetic materials, the dry cementitious materials (powder) and the hydration water. ASTM D8329 provides a step-by-step process for using GCCM sample material to record the mass per unit area of each GCCM component so that the hydration water to cementitious materials ratio can be calculated.

This ratio is then used to prepare cubes of the cementitious material for compressive strength testing. The cementitious material used to form the cubes must be extracted from the GCCM itself and cubes should not be made from manufacturer supplied pre-batched powder mixes that may have a different cement content to the actual GCCM product.