Information contained in this blog post was correct at the time of writing, for the latest information on Concrete Canvas T Series embodied carbon please see the Carbon Comparison Report by Ricardo Energy and Environment.

Is Concrete Canvas® really an environmentally friendly concrete alternative?

The cement industry is one of the two largest producers of carbon dioxide (CO2). As the most widely used man-made material in the world, it’s no surprise that over 4.1 billion tonnes of cement were produced in 2020, along with a resulting 1.5 billion tonnes of CO2.

Global carbon emissions reached an all-time high in 2018, so it’s time the cement industry made some changes. Could Concrete Canvas® be the answer?

In short, Concrete Canvas® (CC) is considerably more environmentally friendly than traditional concretes. Read on to find out why.

Carbon emissions

CC offers significant carbon reductions compared to traditional concrete methods. As stated in Concrete Canvas Ltd.’s CO2 Footprint Report, one square metre of Concrete Canvas used for channel lining will contain only 45% of the Embodied Carbon of an equivalent square metre of conventional poured concrete.

That 55% saving is further boosted when considering transportation. One pallet of CC – or one CC bulk roll – can directly replace two 17-tonne ready-mix concrete trucks. CC is also available in pre-cut, man-portable batched rolls. These formats allow CC to be much more easily transported to and on-site, while vehicle movements are drastically reduced.

For these reasons, CC is often specified for projects on remote sites where use of traditional methods is implausible and will therefore be transported further than locally sourced concrete materials. With all this considered, the reduced logistical requirements result in a 50% reduction in transportation carbon costs.

With regards to the installation itself, CC can be installed ten-times faster than poured concrete; while this will vary on a project to project basis, further savings can be made in the construction installation process carbon costs.

Environmental impact of installation

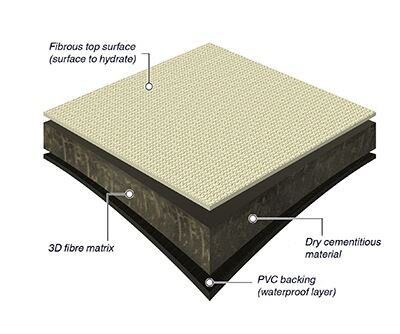

CC consists of a PVC backing, a three-dimensional fibre matrix at its core, and a polyester fibrous top surface. The specialist cementitious material is trapped within the 3D matrix which limits loss of material during the installation process.

As a result, CC can be installed and hydrated within live watercourses with minimal loss of fines at around 3% compared to the average of 10-15% experienced when using specialist underwater concretes (CC Environmental Data document).

CC uses a specialist high early strength concrete with a limited alkaline reserve. Unlike most concretes, it is not classed as an irritant, and the PVC backing is a high grade, phthalate-free compound chosen to minimise the product’s impact on the environment. As a result, CC can safely be installed on environmentally sensitive sites without any adverse effects on wildlife or the local ecology.

CC’s eco-friendly properties have led to its use on numerous sensitive sites and specification by several environmental agencies around the world, including public works projects for Environment Agency, National Resources Wales and Scottish Environmental Protection Agency in the UK.

Carbon absorption

The fibrous top surface layer of CC is the perfect surface for the growth of moss and algae, particularly in channel lining applications where the surface is generally moist and provides the perfect conditions for growth.

This not only results in the material ‘greening’ over time for a more natural appearance, but can theoretically assist in balancing out CC’s carbon impact.

Scientists at the Max Planck Institute for Chemistry found that these organisms absorb large amounts of CO2 and remove nitrogen from the air in order to “fix” it to the form required for their growth.

The study undertaken at the Max Planck Institute discovered that algae, mosses and lichens take up around 14 billion tonnes of CO2 and fix around 50 million tonnes of nitrogen every year.

As a result, the growth of these organisms on CC’s surface will assist in reducing CC’s environmental impact over the BBA certified 120-year durability of the CC lined asset.